Details

- 商品详情

PRODUCT DESCRIPTION

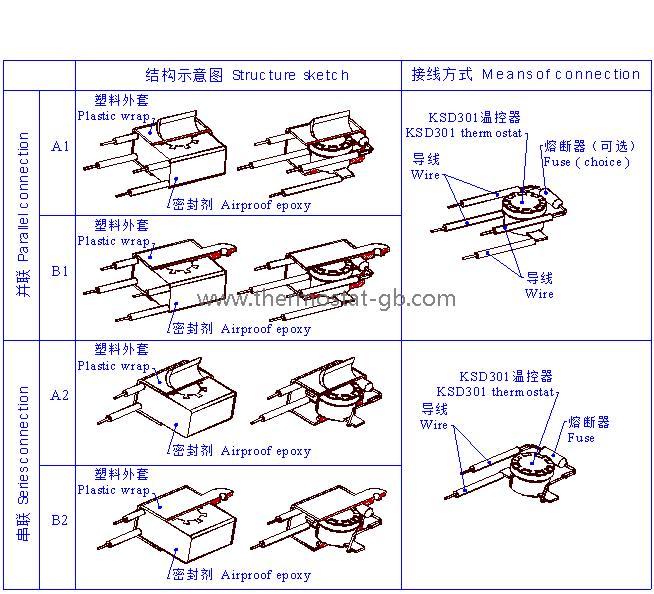

KSD303-D series snap-action defrost thermostat is a kind of miniature waterproof and hermetically seal bimetal thermal protector. It is of single-pole single-throw structure and works under resistive load. Thermostat is enveloped in cold-resistant and flame-retardant plastic tube or sealing gum for possible underwater applications. The product series is widely used as heating compensated switch or automatic defrosting control switch in air-cooling frostless refrigerators.

BASIC TECHNICAL PARAMETERS

| Uses: | Defrost/temperature control/protection | Application: | Refrigerator (waterproof thermostat, refrigerator thermostat) |

| Housing material: | Bakelite | Current: | 3A/10A/16A |

| Maximum operating temperature: | 40℃ | Temperature difference: | for reference |

| Tolerance: | for reference | Minimum tolerance: | 10℃ |

| Contact material: | silver | Insulation resistance: | With a DC 500V megger, borne DC 500V, the tested value is over 100 MW. |

Dielectric Strength (in water): | In water, parts between the terminals and airproof wrap can bear 1500V 50Hz AC current, which is nearly sine wave, for one minute as bearing test. Resulted no breakdown, no flash-over. | Cold-resistant Temperature: | -40℃ |

| Reset type: | Auto Reset | T Max: | 90℃ |

| Class of Temperature Characteristics: | Normal close, normal open |

PRODUCT ADVANTAGES

| ●Waterproof; ●High precision; ●Fast heat transfer; ●High durability; ●No breakdown, no arcing; ●Each thermostat will be tested and the temperature pass rate is high. |  |

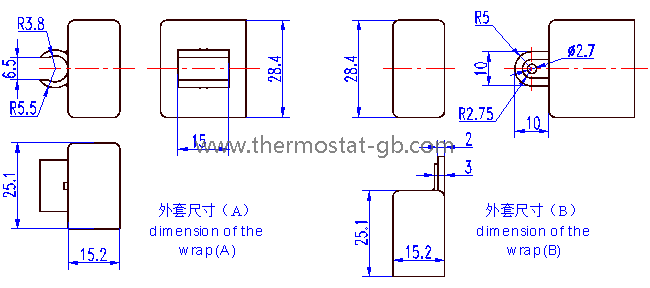

DIMENSION OF THE MAIN BODY

SAFETY CERTIFICATE

| Rates | Life cycles | Max. OT | Certificate |

| 250V 10A | 30,000 | 40°C | TUV |

ORDER DETAILS

| package | 200-500/ inner box, box size: 480 (length) * 282 (width) * 218 (height) (mm) |

| minimal order size | 1000 |

| payment method | Wire transfer, Western Union |

| delivery time | 15 to 20 days |

INSTALLATION AND DIRECTION FOR USE

| Installation and use instructions: |

| 1. Grounding method: Connected to the grounding metal parts of the equipment through the metal casing of the thermostat. 2. The thermostat shall be operated in a general indoor environment where the relative humidity of the air is not more than 90%, no corrosive gas, no flammable gas and conductive dust. 3. When the temperature controller is in contact with the temperature, the cover should be placed close to the heat-generating part of the controlled appliance, and the thermal surface of the cover should be coated with thermal grease or other similar heat-conducting medium. 4. When the temperature controller is exposed to liquid or steam, it is recommended to use a stainless steel cover and a reliable leak-proof measure to prevent liquid from seeping into the insulation of the thermostat. 5. It is not possible to collapse or deform the top of the cover to avoid changes in operating temperature or other properties. 6. Do not allow liquid to penetrate inside the thermostat! The housing must be protected from excessive forces to prevent cracking; the housing should be kept clean to prevent contamination of conductive materials to prevent short-circuit breakdown due to reduced insulation. 7. The terminal cannot be bent during use, otherwise the reliability of the electrical connection will be affected. |